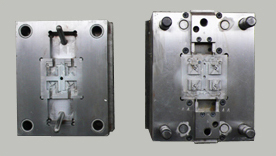

Precision Mold Making

We have extensive experience in Injection Mold making and we know tooling of the mold is an important step in making good designs into practical and precise parts and gears. Here at Plagears, we design and build injection molding cavities and precision tools for both precision gear and non-gear applications. Our gear cavities or inserts are made to ensure they are precise and capable of handling high temperature and production volume because the molds form large number of gears and parts. We build single and multi-cavity molds and provide reliable injection molds and gears and work with customer closely on drawing design and modification to achieve the goals no matter our customers have expertise in injection molding field or not.

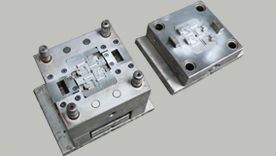

We provide sample injection molded components and gears within a short time, depending on the complexity and how close they must be to production quality. There are needs for quick precision molded sample parts and gears for customer approval so we have long ago developed a flexible tooling system that can accommodate variations in parts type and size for our customers. The resulting samples that the molds produce thus can be very close to full production quality. Our customers are able to shorten their development cycle while saving money for production.